- Home

- Products

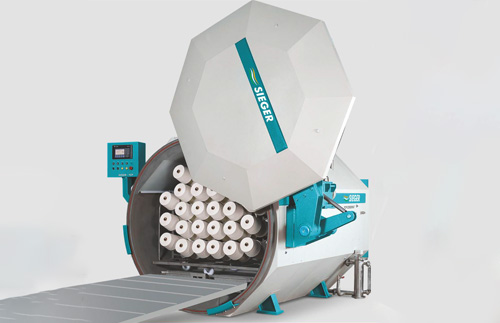

Yarn Conditioning Plant - YCP

Yarn Conditioning Plant - YCP

Principle of Conditioning

In Sieger Yarn Conditioning Plant YCP, conditioning is carried out by cold saturated Steam generated outside the plant. Steam is generated in accordance with the vapour pressure curve of steam, to maintain homogeneity.

Effect

Homogeneous penetration of moisture is ensured by several stages of evacuation and impregnation with saturated steam. Precision sensors with perfect reproduction system ensures consistent performance within and between batches for years of operation.

Parameters involved

| Material | Temperature ®C | Soak Time | Total Time |

| Cotton Waxed | 55-60 | 25-30 | 55 min |

| Cotton Unwaxed | 60-80 | 20-25 | 60 min |

| P/C , P/V | 80-90 | 30-40 | 60 min |

| Viscose | 60-65 | 25-30 | 55 min |

| Wool | 70-80 | 20-25 | 60 min |

Process fine tuning is done at site depending on the yarn to obtain maximum results. Constant research has enabled us to perfect the art of conditioning.

SIEGER Yarn Conditioning Plant

| Description | YCP 200 | YCP 350 | YCP 600 | YCP 1000 | YCP 1250 | YCP 1500 | YCP 2000 | |

| Capacity / Batch | Kgs | 200 Kg | 350 Kg | 600 kg | 1000 Kg | 1250 kg | 1500 kg | 2000 kg |

| Production / Day | Ton | up to 4.6 | up to 8.1 | up to 13.8 | up to 23.0 | up to 28.8 | up to 34.5 | up to 46 |

| Diameter | mm | 1400 | 1400 | 1800 | 2000 | 2000 | 2000 | 2000 |

| No. of Trolleys / Batch | nos | 1 | 3 | 3 | 4 | 5 | 6 | 8 |

| Loading Type | Manual | Auto | Auto | Auto | Auto | Auto | Auto | |

| Heating Type | std | Electric | Electric | Electric | Electric | Electric | Electric | Electric |

| opt*-1 | Steam | Steam | Steam | Steam | Steam | Steam | Steam | |

| opt*-2 | Gas | Gas | Gas | Gas | Gas | Gas | Gas | |

| Required Floor Space in mm | L | 6,000 | 11,000 | 11,500 | 13,000 | 14,350 | 16,100 | 19,000 |

| W | 3,800 | 4,400 | 5,200 | 5,300 | 5,300 | 5,300 | 5,300 | |

| H | 2,500 | 2,500 | 3,300 | 3,300 | 3,300 | 3,300 | 3,300 | |

| Size of the Foundation in mm | L | 4,100 | 5,660 | 6,000 | 6,950 | 7,500 | 8,500 | 9,800 |

| W | 2,400 | 2,400 | 3,100 | 3,300 | 3,300 | 3,300 | 3,300 | |

| Power (Peak Load) | Kw | 36 | 60 | 90 | 120 | 150 | 180 | 210 |

| Machine weight (approx) | Tons | 2.0 | 3.0 | 3.5 | 3.5 | 4.0 | 5.0 | 5.5 |

|

* Production / day depends on capacity / batch & process parameters. * Capacity considering a standard package diameter 210mm & standard package weight 1.890 kgs. * High temperature special module is available for twist setting. * Technical details given are subject to change without prior notice. |

||||||||