- Home

- Products

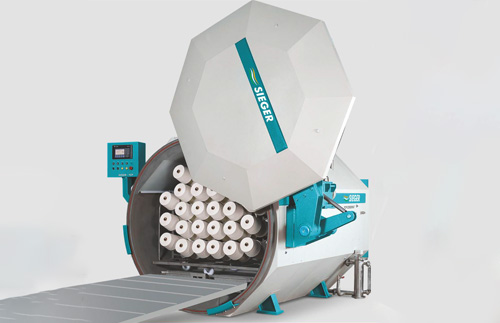

Yarn Conditioning Plant - YCP Autoline + Preconditioning

Yarn Conditioning Plant - YCP Autoline + Preconditioning

Principle of Conditioning

SIEGER has developed a state of the art fully automatic Autoline YCP with pre and post conditioning system to impart right amount of moisture under controlled conditions resulting in consistent yarn quality. The SIEGER YCP AUTOLINE with pre conditioning is available in different capacities and in different layouts to suit the customer requirement.

Product Highlights

- Unique technology from sieger for higher moisture gain upto ~2.5%

- Fully automated system

- Short ROI within a year

- Trolley movement inside plant of FIFO principle

YCP Autoline - Pre Conditioning - Only

| Material | 750 PC | 1000 PC | 1500 PC | 2000 PC | |

| Capacity / Batch | Kgs | 750 | 1000 | 1500 | 2000 |

| Production / Day | Ton | 16500 | 22000 | 33000 | 44000 |

| No of Trolleys in PC room | 15 | 20 | 30 | 40 | |

| Loading Type | Auto | Auto | Auto | Auto | |

| Required Floor Space- MM | L | 9300 | 11400 | 14900 | 20800 |

| W | 8300 | 8300 | 8300 | 8300 | |

| H | 3500 | 3500 | 3500 | 3500 | |

| Basic Size of The Plant | L | 9000 | 11100 | 14600 | 20500 |

| W | 8000 | 8000 | 8000 | 8000 | |

| H | 3100 | 3100 | 3100 | 3100 |

Yarn Conditioning Plant - YCP Autoline + Preconditioning

| DESCRIPTION | 750 AL | 1000 AL | 1500 AL | 1000 AL | 1500 AL | 2000 AL | 1000 AL | 1500 AL | 2000 AL | |

| L-TYPE | U-TYPE | STRAIGHT TYPE | ||||||||

| Production / Day | Kgs | 16500 | 22000 | 33000 | 22000 | 33000 | 44000 | 22000 | 33000 | 44000 |

| Pre Con - No. of Trolleys | 15 | 20 | 30 | 20 | 30 | 40 | 20 | 30 | 40 | |

| No. of YCP Trolleys | 3 | 4 | 6 | 4 | 6 | 8 | 4 | 6 | 8 | |

| Loading Type | Auto | Auto | Auto | Auto | Auto | Auto | Auto | Auto | Auto | |

| Connected Load | Kw | 157 | 192 | 239 | 192 | 239 | 275 | 192 | 239 | 275 |

| Required Floor Space-mm | L | 16170 | 19050 | 23230 | 17260 | 22270 | 27540 | 29580 | 40000 | 50660 |

| W | 14910 | 17440 | 21610 | 12170 | 12550 | 12110 | 11200 | 11200 | 11200 | |

| H | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | 3500 | |